The Right Enclosure

A new company focused on indoor air quality developed a technology that kills airborne and surface contaminants including bacteria, mold and pet dander. The components were relatively simple: two UV lamps, two fans, an air filter and three air reactor pads. But it needed the perfect package — something that would complement its impressive capabilities — something with an industrial feel and hospital grade that could be used in a variety of environments including residential, school gyms and locker rooms and kennels.

Inspiration from a Wooden Box

The new company approached Southern and presented a wooden box model as a rough example of what they wanted. Southern was tasked to make the enclosure out of stainless steel for a high-end look and was given the liberty to create the proper enclosure to house the components. Taking a smart design approach, plans were developed and finalized to build the enclosure as simply and cost effective as possible.

Laser & Rivet Ready

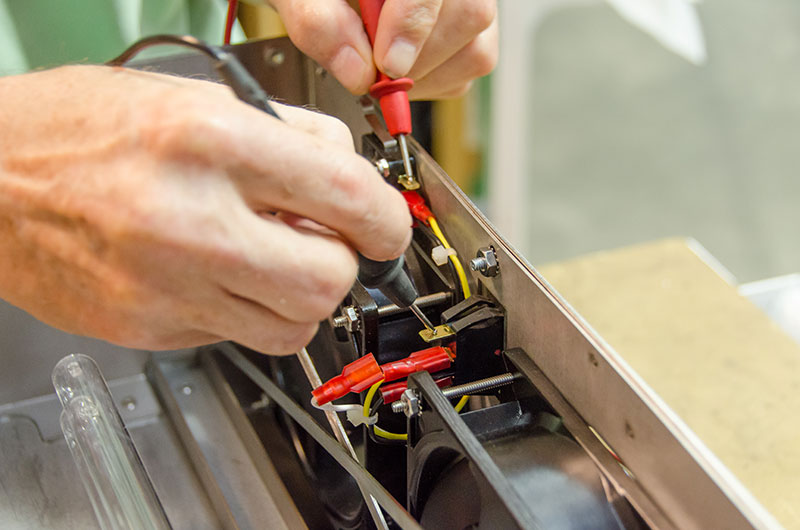

Southern’s state-of-the-art laser machines cut all of the steel used for the enclosure based on strict specifications. A hydraulic press brake was used for all of the expert bending. Rivets to attach all the parts were fastened using a pneumatic rivet gun which speeded up assembly time and ensured that all of the holes lined up perfectly. Southern then sourced and installed all of the internal components.

An Ongoing Turnkey Solution

We continue to produce and stock two model sizes for this client. Our client is comfortable knowing that the enclosures will be made to perfection and assembled properly with their proprietary, internal components then drop-shipped directly to their customers. Producing hardware that is tailor-made for the client — that is our passion and our specialty.

Start Your Project Quote Today

Ready to start your next project? Fill out the form below to best assess your needs or contact us.